POWER LIFT HL 2.40 NT W UNI

Hydraulic 2 post lifts with UNI arms for car wash facilities

POWER LIFT HL 2.40 NT W UNI

Item No:HLNT240.0010021D-0000

Compare

Brief description

Matchcode:

HLNT240.0010021D-0000

Item No:

0001053

Lifting capacity:

4000 kg

Type

2 post lifts

Color

Hot-dip galvanized

Dealer in your area

91

Not your postcode? enter here

More dealers

Nussbaum Automotive Lifts, Inc.

177 Defense Highway Suite 7, Annapolis

Maryland 21401

https://

| Capacity | 4000 kg |

|---|---|

| Lower swivelling height | 115 - 190 mm |

| Length front arm | 570 - 1160 mm |

| Length rear arm | 1130 - 1840 mm |

| Lifting time | 26 sec. |

| Lowering time | 14 sec. |

| Lifting height max. | 2050 mm |

| Required ceiling height | 4182 mm |

| Total height | 4040 mm |

| Total width | 3350 mm |

| Clear distance between columns | 2522 - 2766 mm |

| Electrical connection (Ph/V/Hz) | 3 Ph , 400 V , 50 Hz |

| Fuse protection | 16 Amp. slow-blow |

| engine power | 3 KW |

Datasheets

| Data sheet HL 240 NT W UNI | 220 KB |

Foundation plans

| Foundation plan HLNT-HF-HF 3S | 53 KB | |

| Cube foundation plan HLNT_HF 3S_SLH | 70 KB |

Force Diagrams

| Force diagram HL 240 NT | 247 KB |

Dowel drilling patterns

| Data sheet HL 240 NT UNI - HF 3S 4000 UNI | 211 KB |

Liftingpatterns

| Pick up diagrams SL 240 - HL 240 NT - HF 4000 - HF 3S 4000 | 590 KB |

Inspection books

| POWER-LIFT HL 2.40 NT WHV EN | 9 MB | |

| POWER-LIFT HL 2.40 NT WHV DE FR IT | 9.8 MB |

Leaflets

| POWER LIFT HL NT Broschüre - Deutsch | 1.5 MB | |

| POWER LIFT HL NT Brochure | 1.4 MB |

1

| Packaging | |

|---|---|

| Product Dimensions | 4120mm x 800mm x 600mm |

| Total weight | 730kg |

| Stackable | 3 times |

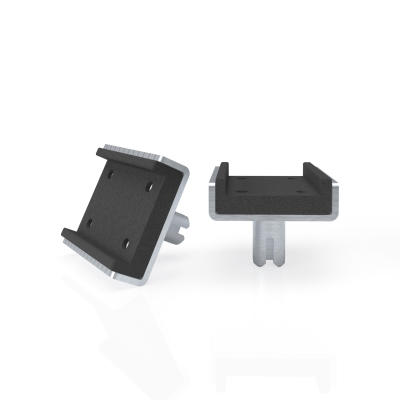

Height extension

Matchcode: 230HLNT90200-0000

Item No: 0007225