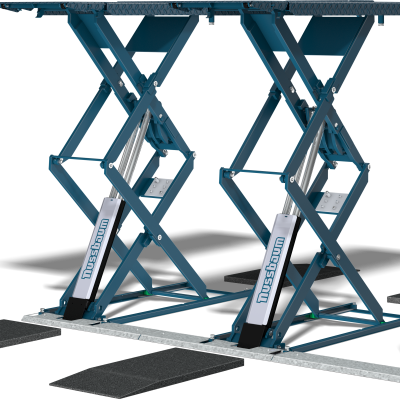

JUMBO LIFT 3500 NT

Hydraulic double scissor lift

JUMBO LIFT 3500 NT

Item No:JLB035.0021000D-7016

Customize

Compare

Brief description

Matchcode:

JLB035.0021000D-7016

Item No:

0000035

Lifting capacity:

3500 kg

Type

Doublescissor lifts

Color

grey

Dealer in your area

91

Not your postcode? enter here

More dealers

Nussbaum Automotive Lifts, Inc.

177 Defense Highway Suite 7, Annapolis

Maryland 21401

https://

| Capacity | 3500 kg |

|---|---|

| RAL colour | RAL 7016 |

| Installation type | above ground or inground |

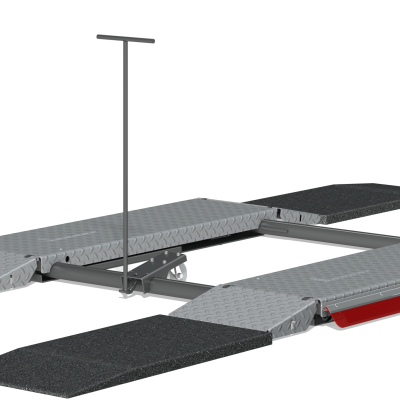

| Platform length | 1460 - 2158 mm |

| Lifting/lowering time | 35 sec. |

| Lifting height | 2000 mm |

| Recommended installation width | 2020 mm |

| Platform width | 610 mm |

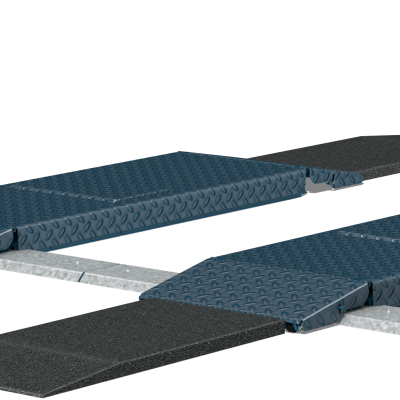

| Drive-on height | 105 mm |

| CE-Stop | yes |

| Electrical connection (Ph/V/Hz) | 3 Ph , 400 V , 50 Hz |

| Fuse protection | 16 Amp. slow-blow |

| engine power | 3 KW |

Datasheets

Force Diagrams

| Force diagram JUMBO LIFT 3500 NT HF | 28 KB |

Liftingpatterns

| Pick up diagrams JUMBO LIFT 3500 NT | 335 KB | |

| Pick up diagrams JUMBO LIFT 3500 HF | 44 KB |

Inspection books

| JUMBO-LIFT 3500 NT / 3500 HF X-Tend_DE EN FR ES IT | 11 MB |

Leaflets

| JUMBO LIFT Broschüre - DE | 1.8 MB | |

| JUMBO LIFT Brochure | 1.8 MB | |

| JUMBO LIFT Panfleto - ES | 1.8 MB | |

| JUMBO LIFT Brochure - FR | 1.8 MB | |

| JUMBO LIFT Prospetto - IT | 1.8 MB |

1

| Packaging | |

|---|---|

| Product Dimensions | 1780mm x 770mm x 770mm |

| Total weight | 850kg |

| Stackable | Not stackable |